What is Nonwoven Fabric?

Definition, Key Features, and Applications

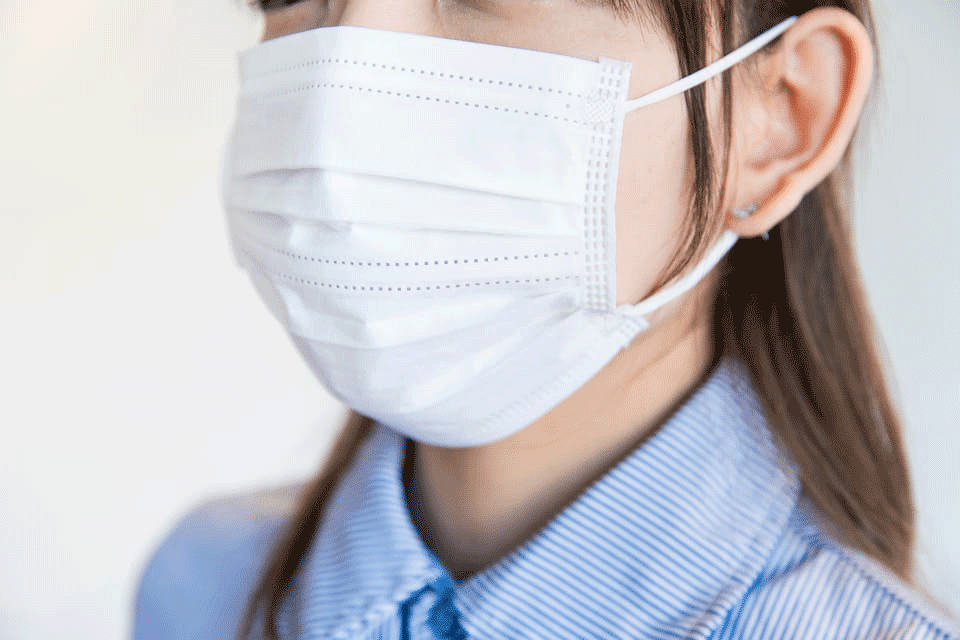

Nonwoven fabric is an essential material not only for daily applications such as masks and diapers but also for industrial purposes. It has become indispensable in our lives. On this page, Hirose Paper Co., Ltd., we have over 60 years of research and development experience, will explain in detail what nonwoven fabric is.

Table of Contents

Overview and Definition of Nonwoven Fabric

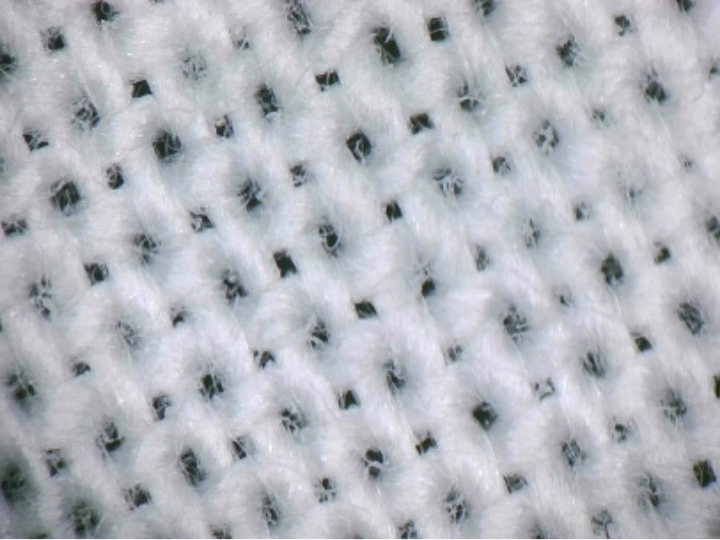

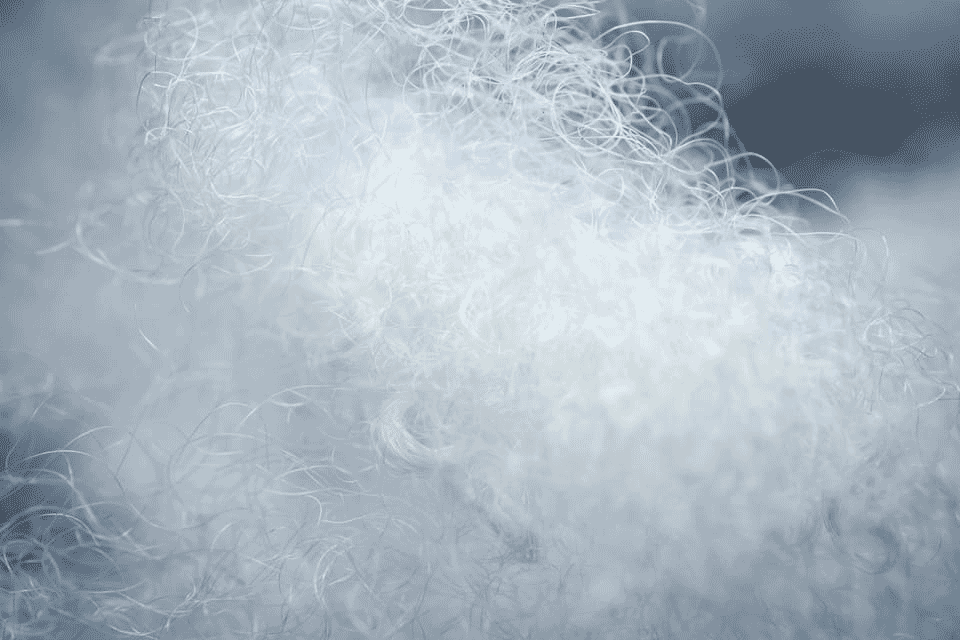

As the name suggests, nonwoven fabric refers to fabric made without weaving fibers. It is created by arranging fibers either randomly or in a specific direction and then bonding them through thermal, chemical, or mechanical processes. Compared to woven or knitted fabrics, nonwoven fabric lacks the interwoven structure of threads, giving it distinct functionalities and features that other fabrics do not possess.

- Nonwoven Fabric

- Woven Fabric

- Knitted Fabric

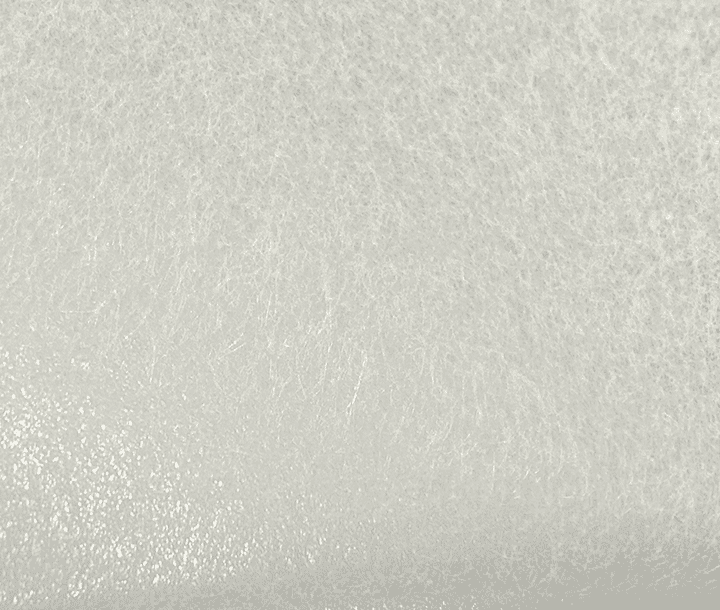

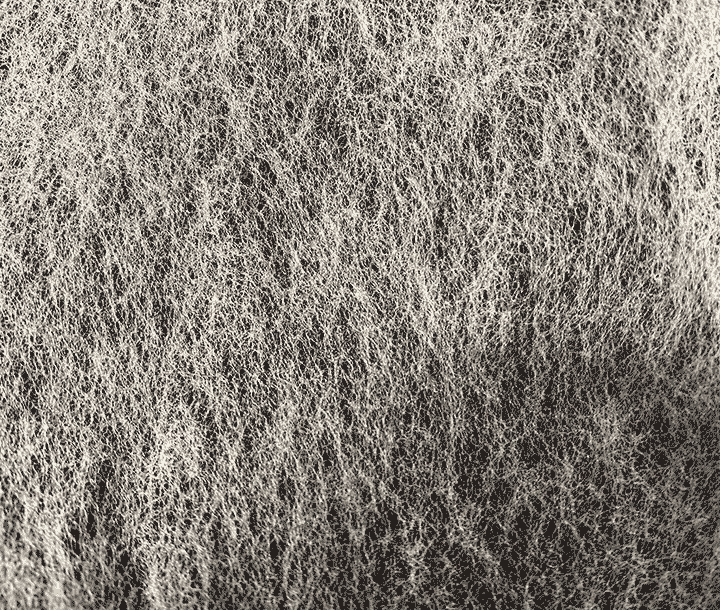

Nonwoven fabric can range from thin, paper like sheets to thick, mat like materials, as its density and thickness can be adjusted to suit different applications. The surface texture also varies significantly depending on the materials and manufacturing methods. For example, when softness is a priority as with clothing, smooth materials like cotton or silk are used. Conversely, for applications that demand slip resistance such as mats, it is adjusted both the material and the manufacturing process to create a rougher surface.

- Smooth Texture

- Rough Texture

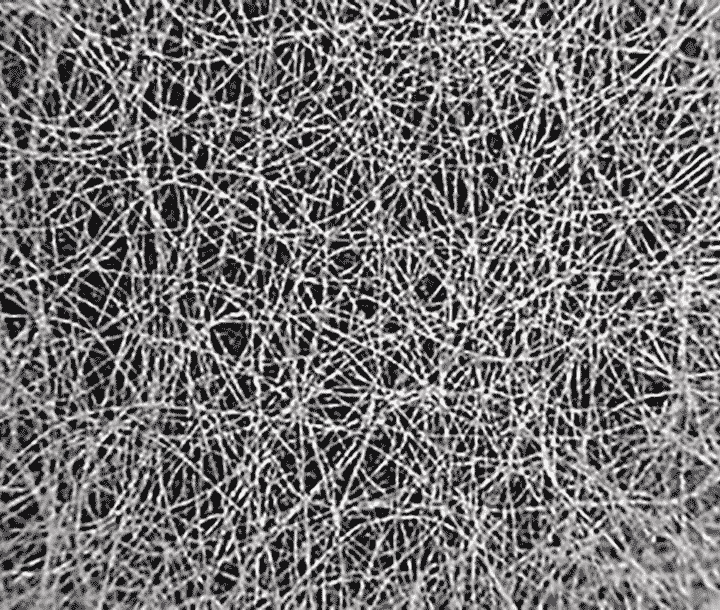

- Highly Breathable

Common Applications of Nonwoven Fabric

Nonwoven fabric is widely used in disposable products and medical hygiene supplies, including:

- Medical

- Hygiene

- Food packaging materials

- Shopping bags

- Water purification filters

Recent advances in manufacturing technology have led to nonwoven fabrics being used more frequently for high-performance applications such as:

- Automotive components

- Industrial filters

- Lithium-ion battery separators

Hygiene and medical uses remain the most in demand, but in recent years high-performance applications for automotive and other industries have also grown, and nonwoven fabrics are expected to see expanding use across a wide range of fields.

For more detailed information on the applications of nonwoven fabric, please refer to our page on primary applications of nonwoven fabric.

page on primary applications of nonwoven fabric.

Unique Features – Advantages and Disadvantages

Nonwoven fabrics are made by entangling fibers, resulting in a porous structure with many tiny holes. In other words, there are ample gaps between the fibers, and this porosity gives nonwovens a number of benefits such as breathability, absorbency, light weight, and cost effectiveness.

Advantages

Breathability & water permeability

The voids between fibers allow air and water to pass through easily, making nonwovens ideal for filters think face masks or water-filtration units.

Absorbency and Moisture Retention

Those same inter fiber spaces can hold liquid, which is why you’ll find nonwoven layers in diapers, sanitary pads and other personal-care products.

Lightweight

All those air-filled pores make nonwovens exceptionally light. That low weight not only cuts shipping costs but also makes single use items easy to handle. That’s why diapers are so airy and light.no wonder a pouch of diapers feels so airy.

Flexibility

Because fibers aren’t tightly woven, nonwovens bend and conform readily. They can be cut or molded to nearly any shape or size without losing integrity.

Cost-Effectiveness

Skipping the weaving or knitting steps means nonwovens can be made rapidly and at lower cost than traditional fabrics.

Moreover, by tweaking the size, shape and distribution of those pores and by choosing different raw materials or bonding methods, you can tailor nonwoven fabrics for extra strength, heat resistance, chemical resistance and a host of other specialized functions.

Disadvantages

Nonwoven fabric exhibits lower resistance to abrasion and tensile forces compared to woven or knitted counterparts. This is primarily because the fibers in nonwoven fabric are bonded rather than interwoven, resulting in a structure that lacks the systematic reinforcement of woven or knitted materials. As a result, nonwoven fabric may wear out faster or tear under significant stress, making it less suitable for applications requiring high durability without additional reinforcement. These issues can be mitigated by blending strong materials or applying thermal bonding techniques.

Raw Materials and Manufacturing Process

Nonwoven fabric is made from two main types of fibers: natural fibers, such as cotton and hemp, which are derived from natural sources, and synthetic fibers, like polyethylene and polyester, which are artificially created. Synthetic fibers are more commonly used due to their superior heat and chemical resistance compared to natural fibers. On the other hand, natural fibers are gaining attention as an environmentally friendly option because they decompose more easily after use.

Natural Fibers

Derived from natural sources like cotton, bamboo, hemp, wool, and silk, these fibers are ideal for applications involving food or skin contact due to their lack of chemical additives.

Man-made fibers

Man-made fibers is major type of nonwoven fabrics, their varied properties making them suitable for applications that range from everyday household items to heavy-duty industrial uses. Depending on how they are made, chemical fibers fall into two main categories: synthetic fibers, which are created from petrochemicals, and regenerated fibers, which are produced by chemically treating natural polymers. Both types offer advantages over natural fibers, particularly in terms of heat resistance and resistance to chemicals. Common examples include polyethylene, polypropylene, polyester, nylon, rayon and acetate.

For more information about type and features of each materials, visit our:

page on raw material types and their features.

Manufacturing processes

The production of nonwoven fabric can be divided into four main stages: raw material selection, web formation, web bonding, and finishing. From the web formation stage onward, each step determines the fabric’s ultimate structure and performance.

First comes web formation, where loose fibers are laid out into a continuous sheet. There are a variety of techniques (some use water, others don’t) and each method yields a sheet with its own characteristic texture and strength.

Next is web bonding, in which those fibers are fused together to give the material integrity and specific physical properties. This bonding can be achieved in four principal ways:

- Mechanical bonding, where fibers are physically entangled (for example, by needling)

- Chemical bonding, using adhesives to stick fibers together

- Solvent bonding, where a solvent partially dissolves fiber surfaces so they fuse as the solvent evaporates

- Thermal (or thermo‐mechanical) bonding, applying heat and pressure to meld fibers at their contact points

Finally, the finishing stage adds any special treatments or coatings to enhance performance, appearance, or hand feel—everything from water repellency and flame resistance to coloration or softness.

Because each step from how the web is formed to the bonding method and finishing treatment directly shapes the nonwoven’s properties, it’s absolutely vital to tailor every process choice to the fabric’s intended application. For a more in‐depth look at the various manufacturing routes and their resulting features, you can refer to the detailed overview here:

Types and Features of Nonwoven Fabric Manufacturing Processes

For more on manufacturing methods, visit our:

page on production methods and characteristics.

A History of Nonwoven Fabric

The origins of nonwoven fabric can be traced back to German felt manufacturers who bonded wool scraps with adhesives. Industrial production began in 1930 when a patent was obtained in the United States. Although demand initially grew slowly, the industry began to expand significantly in 1952 when the American company Pellon introduced affordable, breathable, and tear-resistant nonwoven fabric.

In Japan, interest in nonwoven fabrics suddenly surged around 1954 after the Beron Company introduced the technology. Then, in 1956, several felt making firms imported U.S. equipment and began producing “dry” nonwovens fabrics made without any water. Shortly afterward, Kinsei Paper Co., Ltd., succeeded in manufacturing dry nonwovens on domestically built machinery, officially kicking off local production. In 1958, Hirose Paper Co., Ltd. applied traditional washi papermaking techniques to produce Japan’s first wet laid nonwoven fabric made entirely of Vinylon fibers, marking the full flowering of Japan’s nonwoven industry.

References:

Tsuchibayashi, Sadao. Nonwoven Fabrics for Apparel and Industrial Use. Sen’i Gijutsu Kenkyūsha, 1960.

Shirakashi, Kan. Nonwoven Fabrics. Nikkan Kogyo Shimbun Co., Ltd., 1965.

Over the years, innovations in nonwoven technology around the globe have led to the development of numerous manufacturing methods, transforming the industry into the powerhouse it is today.

Consult Us for Nonwoven Fabric Solutions

Nonwoven fabric’s features and functions vary greatly depending on its manufacturing methods and raw materials, making it challenging to select the right product for specific purposes.

At Hirose Paper Co., Ltd., we have over 60 years of research and development experience in nonwoven fabrics, leading the global industry with innovations such as:

- 100% synthetic fiber-based nonwoven fabric

- The world’s thinnest papermaking technology (2 g/m² with 100% polyolefin fibers)

- Nanofiber nonwoven fabric using electrospinning technology

We also specialize in applications such as lithium-ion battery separators, functional air filters, and medical-grade nonwoven fabrics.

For inquiries or assistance, feel free to contact our expert team. We’re here to help!