Main Applications of Nonwoven Fabric

Nonwoven fabric refers to a sheet-like material created by bonding or interlocking fibers. This unique material exhibits various functionalities depending on the raw materials and manufacturing methods. This page provides a detailed explanation of how nonwoven fabric is utilized in everyday products and industrial applications, including automotive uses.

Related Page: What is Nonwoven Fabric?

Table of Contents

Overview of Nonwoven Fabric Manufacturing Process

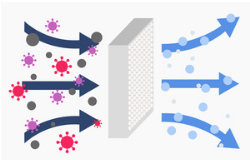

Nonwoven fabric is widely used in everyday items like masks, food packaging, and diapers, as well as industrial applications such as liquid and gas filters and automotive interior bases or reinforcements.

The graph below, published by the Ministry of Economy, Trade, and Industry (METI) in June 2022, illustrates trends in the domestic production of nonwoven fabric by application. The clear classification of applications serves as the basis for the detailed discussion that follows.

According to these findings, the most common use of nonwoven fabric in 2021 was for food packaging and household-related items such as kitchen, laundry, and toilet products. The second most common use was for medical and hygiene products like masks and disposable diapers. Over a six-year period from 2015 to 2021, production for medical and hygiene uses decreased, while industrial applications such as filters and battery separators showed an upward trend. This suggests a gradual shift in Japan’s nonwoven fabric production focus from general-purpose uses to high-functionality applications.

Specific Applications by Category

Next, let’s take a closer look at the specific uses within each category. Many nonwoven fabric applications involve products designed to be replaced or disposed of after contamination or wear. Keeping this perspective in mind may help you better understand how nonwoven fabric is utilized.

Household-Related Uses

This category primarily includes items we naturally use in our daily lives. Examples include protective paper for sponge cakes, tea bags for brewing, and mats for bathrooms or kitchens. Due to their frequent contact with food and human skin, environmentally friendly and non-toxic materials are often used in this category.

| Application | Image | Description |

|---|---|---|

| Food Packaging |  |

Keeps food fresh. Lightweight, durable, and features excellent breathability and moisture absorption. Often made from recyclable, eco-friendly materials. |

| Shopping Bags |  |

Lightweight, durable, washable, and customizable with colorful designs or logos. Often made from reusable materials. |

| Tea Bags |  |

Designed with fiber gaps to prevent tea leaves from escaping while allowing efficient extraction. Offers durability, breathability, and water permeability while ensuring safety and convenience. |

| Towels |  |

Lightweight, flexible, and highly absorbent with quick-drying properties. Commonly used as disposable towels or cleaning cloths. |

| Mats |  |

Durable and versatile for use in wet areas or as ironing pads. Anti-slip nonwoven fabrics are often used in this application. |

| Dishwashing Pads |  |

Fine fiber structures allow cleaning without scratching dish surfaces. Quick-drying and hygienic. |

| Water Purifier Filters |  |

Efficiently traps fine particles and impurities with its microfibrous structure while maintaining smooth water flow. |

Medical and Hygiene Uses

Applications in this category include masks, bandages, and disposable diapers for everyday use, as well as surgical gowns and leukocyte removal filters for advanced medical settings. Disposable medical items are essential for infection prevention, making nonwoven fabrics highly suitable for these applications.

| Application | Image | Description |

|---|---|---|

| Masks |  |

Used as filters to block fine particles. Advanced products use nano-fiber nonwoven fabrics. |

| Bandages |  |

Features high breathability, absorption, and flexibility. Latex-free materials are often used to reduce allergic reactions. |

| Surgical Gowns |  |

Combines breathability, waterproofing, and antibacterial properties. Disposable to maintain a sterile surgical environment. |

| Plaster Bases |  |

Provides comfort with excellent breathability, moisture absorption, and appropriate strength for extended wear. |

| Leukocyte Removal Filters |  |

Adjusts fiber gaps to remove or separate leukocytes. A key application of Hirose Paper’s nonwoven fabric. |

| Disposable Diapers |  |

Maximizes absorbency and breathability to maintain skin cleanliness, reducing the risk of rashes and irritation. Environmentally friendly materials are commonly used. |

Other Uses

| Adhesive Sheets |  |

The micro-holes in the foam resin act as suction cups, enabling repeated attachment and detachment to smooth surfaces like glass and metal. Nonwoven fabric serves as the base material. |

Contact Us for Nonwoven Fabric Solutions

Hirose Paper was the first in Japan to develop wet-laid nonwoven fabric using synthetic fiber vinylon. Building on this success, we have developed a wide range of nonwoven fabrics for daily and industrial uses. Many of the applications introduced in this article utilize Hirose Paper’s nonwoven fabrics. In particular, our PPS nonwoven fabric has expanded opportunities for nonwoven materials in high-temperature, chemical, and high-radiation environments, breaking new ground in industry-first and world-first innovations.

If you have any questions or concerns about nonwoven fabrics, please feel free to contact us.

Our dedicated team of experts is here to assist you with any inquiries or challenges.