What Is the Ideal Highly Oil-Resistant Sheet Material for Fuel Filters?

Nonwoven fabrics are widely known as materials well suited for filtration applications. However, have you ever experienced a loss of strength when using nylon nonwoven fabrics or similar materials for fuel filters handling gasoline or other fuels? In this article, we explain high-performance materials that do not deteriorate even after long-term exposure to fuel, as well as fuel filters optimized for such applications made possible through the successful nonwoven processing of these materials.

目次

Polyacetal with Excellent Resistance to Fuels such as Gasoline

One of the materials with outstanding oil resistance and well suited for fuel filter applications is polyacetal (Polyoxymethylene, POM). POM offers excellent chemical resistance, particularly against organic solvents, gasoline, greases, and synthetic detergents. Except for strong acids such as hydrochloric acid and sulfuric acid, it exhibits high resistance to a wide range of chemicals. As a result, it is an exceptional material capable of maintaining long-term performance even in chemical and fuel environments where conventional nylon or polyester nonwoven fabrics would typically degrade. POM has a repeating –(CH₂–O)– molecular structure and is industrially produced by polymerizing trioxane, a trimer of formaldehyde, under acidic catalysis, followed by the introduction of stabilizing end groups to enhance thermal stability.

Table 1 below compares the chemical resistance of major materials known for their chemical durability. You can clearly see how superior the overall chemical resistance of POM is.

| Type | POM | PA66 | PPE | PBT | PC |

|---|---|---|---|---|---|

| Oil resistance | ++ | ++ | −~× | ++ | −~× |

| Organic solvent resistance | ++ | ++ | −~× | ++ | −~× |

| Acid resistance (low concentration) | +~− | – | ++ | ++ | +~− |

| Alkali resistance (high concentration) | +~− | +~− | ++ | −~× | −~× |

++: Not affected, +: Hardly affected, −: Affected under certain conditions, ×: Affected

(Table 1) Comparison of chemical resistance

Highly Oil-Resistant Nonwoven Filters Made from Polyacetal

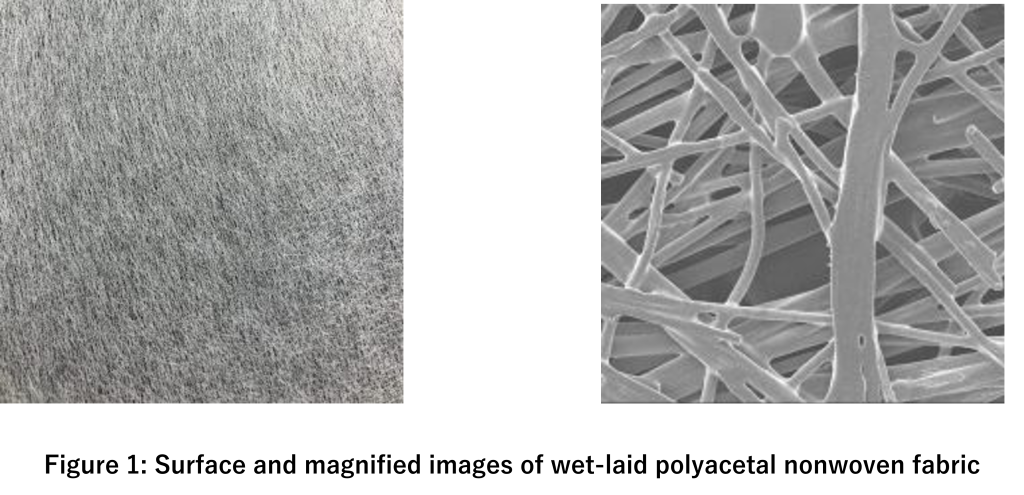

When this chemically robust POM is processed into a wet-laid nonwoven fabric, it becomes a high-performance sheet material ideally suited for fuel filter applications, combining both the intrinsic properties of POM and the structural advantages of nonwoven fabrics. Below is a summary of the key characteristics of POM nonwoven fabrics.

Oil and Organic Solvent Resistance

As described above, POM is not affected by gasoline, alcohols, or oils, and it also exhibits a certain level of resistance to acids and alkalis. Its resistance to organic solvents, gasoline, greases, and synthetic detergents is particularly high, and except for strong acids such as hydrochloric acid and sulfuric acid, it demonstrates excellent chemical durability. Therefore, it can maintain long-term performance even in chemical and fuel environments where conventional nylon or polyester nonwoven fabrics would degrade.

Heat Resistance

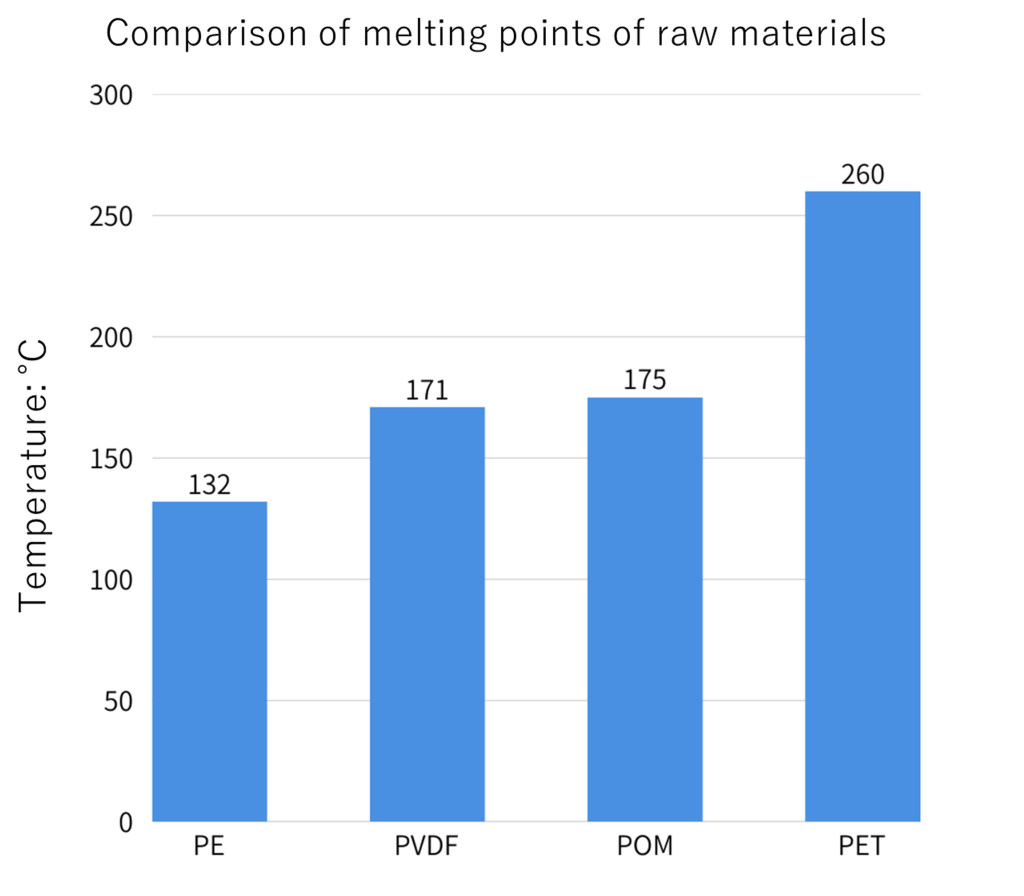

POM has a melting point of 175°C, with a continuous service temperature of approximately 85°C for homopolymers and about 105°C for copolymers, and it can withstand temperatures close to 150°C for short periods. This heat resistance of POM is retained even after conversion into a nonwoven fabric.

High Strength and Durability

POM fibers themselves are extremely tough and resistant to fatigue. As a result, nonwoven sheets composed of 100% POM fibers exhibit excellent tensile strength and tear resistance, and can withstand repeated bending and friction. Inherited from these properties, POM nonwoven fabrics are expected to generate minimal fuzzing and abrasion debris even in applications involving rubbing or bending.

Low Water Absorption, Antibacterial and Anti-Mold Properties

Because POM fibers absorb very little water, POM nonwoven fabrics also tend to retain minimal moisture and dry quickly. This makes it difficult for mold and bacteria to adhere and proliferate, offering excellent hygienic properties. As a result, antibacterial and anti-mold performance can be expected.

Moisture Permeability and Water Resistance

The sheet structure contains countless fine voids between fibers, allowing air and water vapor to pass through easily. At the same time, POM fibers are water-repellent, which makes it difficult for liquid water to penetrate.

Other Applications of Polyacetal Nonwoven Fabrics

With these outstanding functional characteristics across multiple aspects, POM nonwoven fabrics have the potential to be utilized in a wide range of industrial fields. Among them, fuel filter applications for automobiles and industrial machinery mentioned earlier are particularly promising, as POM nonwoven fabrics are expected to serve as filter materials that do not deteriorate even after prolonged exposure to fuels such as gasoline. In addition, by leveraging their chemical and heat resistance, they are considered suitable for specialized chemical filters, HVAC filters, and high-performance filters for cleanroom applications.

Furthermore, due to their low moisture absorption and hygienic properties, applications in medical nonwoven products—such as highly durable gowns, medical filters, and sterilizable masks or filter cartridges—can also be envisioned. In industrial applications, POM nonwoven fabrics may serve as sheet materials that take advantage of their high strength, insulating sheets, chemically resistant filter elements and separation membranes, or abrasion-resistant nonwoven materials for polishing applications, including industrial wipes and buffing pads, thereby opening up opportunities in new markets.

Why Polyacetal Nonwoven Fabrics Were Not Mass-Produced Until Now

Why, then, has POM not been used for fuel filters until now? The reason lies in the intrinsic material characteristics of POM. POM has an extremely fast crystallization rate, and even after melting and extrusion, it crystallizes rapidly during cooling. This makes it prone to filament breakage and embrittlement during the fiber drawing (stretching) process. In addition, POM has a high melting point and a narrow thermal bonding temperature range, and if overheated, it thermally decomposes and generates formaldehyde gas, making it difficult to handle. Furthermore, even if fibers can be produced, POM is hydrophobic and has a relatively high density of 1.4, which makes uniform dispersion—a prerequisite for sheet formation—challenging in the preforming process.

Overcoming these challenges requires polymer modifications (such as adjustments to molecular structure, molecular weight, and composition) as well as optimization of fiberization and papermaking conditions. Due to this high level of technical difficulty, POM had not previously been used in nonwoven fabric production. However, through close collaboration with our partners, we have successfully overcome these challenges and achieved, for the first time in the world, the practical commercialization of a wet-laid nonwoven fabric made from 100% POM resin.

Conclusion

The 100% POM wet-laid nonwoven fabric, which Hirose Paper Manufacturing has commercialized for the first time in the world, combines the excellent mechanical properties, heat resistance, chemical resistance, low moisture absorption, and antibacterial characteristics of POM with the functional advantages of wet-laid nonwoven fabrics. By utilizing this nonwoven material, innovation is expected across a wide range of fields, including filters for gasoline and other fuels, separation membranes, medical nonwoven products, and industrial materials such as abrasive nonwoven fabrics.

We are able to supply this POM nonwoven fabric, and if you are interested, please feel free to contact us for a consultation. Our team of specialists will be happy to assist you. We also welcome inquiries regarding other types of nonwoven fabrics, so please do not hesitate to reach out.