Polyolefin Fiber 100% Wet-Laid Nonwoven Fabric

HOP/UOP Type

The HOP/UOP type is a wet-laid nonwoven fabric composed of 100% polyolefin, characterized by its fine texture. It is made exclusively from core-sheath polyolefin fibers, where a polypropylene core is covered with polyethylene. During manufacturing, the polyethylene melts and bonds the fibers together, eliminating the need for adhesives or chemicals. This makes it safe for use in food and medical applications. The basis weight is flexibly adjustable from ultra-light 4 g/㎡ to 80 g/㎡, and the heat-seal temperature is approximately 140°C.

Key Features

- Heat sealability

- Hydrophobicity

- Thermoformability

- Ultra-lightweight

- Chemical resistance

Enlarged Image

- Low basis weight

4 g/㎡

- High basis weight

60 g/㎡

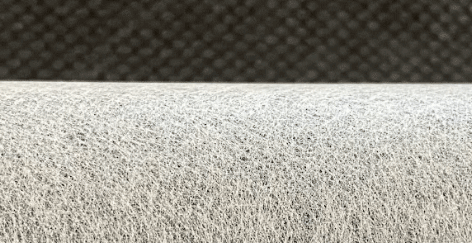

Dry-laid nonwoven

Wet-laid nonwoven (HOP type)

In general, dry-laid nonwoven fabrics tend to have a fuzzy sheet surface structure (image: left). The HOP type, produced using the wet-laid method, disperses fibers in liquid during manufacturing, resulting in a uniform and dense structure that forms a smooth and soft-touch surface (image: right). This soft and smooth surface structure also shows high conformability to contact surfaces, making it ideal for applications in food and medical fields that come into contact with human skin.

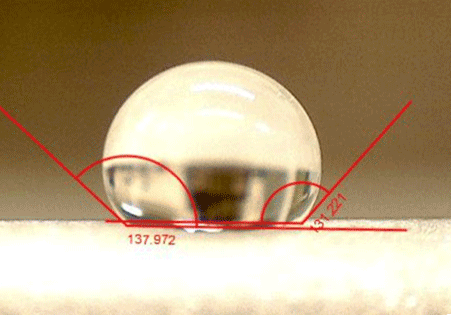

The contact angle when a water droplet is dropped on the surface ranges from 130° to 140°. Materials within this range exhibit strong water-repellent properties and allow liquids to slide easily on the surface, indicating hydrophobicity.

Application Examples

Membrane Support

The HOP/UOP type, with excellent chemical resistance, allows the use of various resins for forming membrane surfaces. By adjusting the density of the support, the thickness and pore size can be controlled, enabling the creation of supports tailored to the characteristics of the resin used.

Separators for Secondary Batteries

The HOP type exhibits excellent chemical resistance and is highly resistant to electrolytes. By combining with secondary processing, the thickness and density can be freely adjusted to meet various specification requirements.

Grade List and Specifications

| Grade | Basis Weight (g/㎡) | Thickness (μm) | Air Permeability (cm³/cm²/s) |

|---|---|---|---|

| HOP-4H | 4.2 | 20.0 | 271.7 |

| HOP-30H | 30.2 | 91.0 | 75.2 |

| UOP-60 | 59.6 | 177.0 | 45.0 |

| UOP-80S | 80.7 | 173.0 | 14.4 |