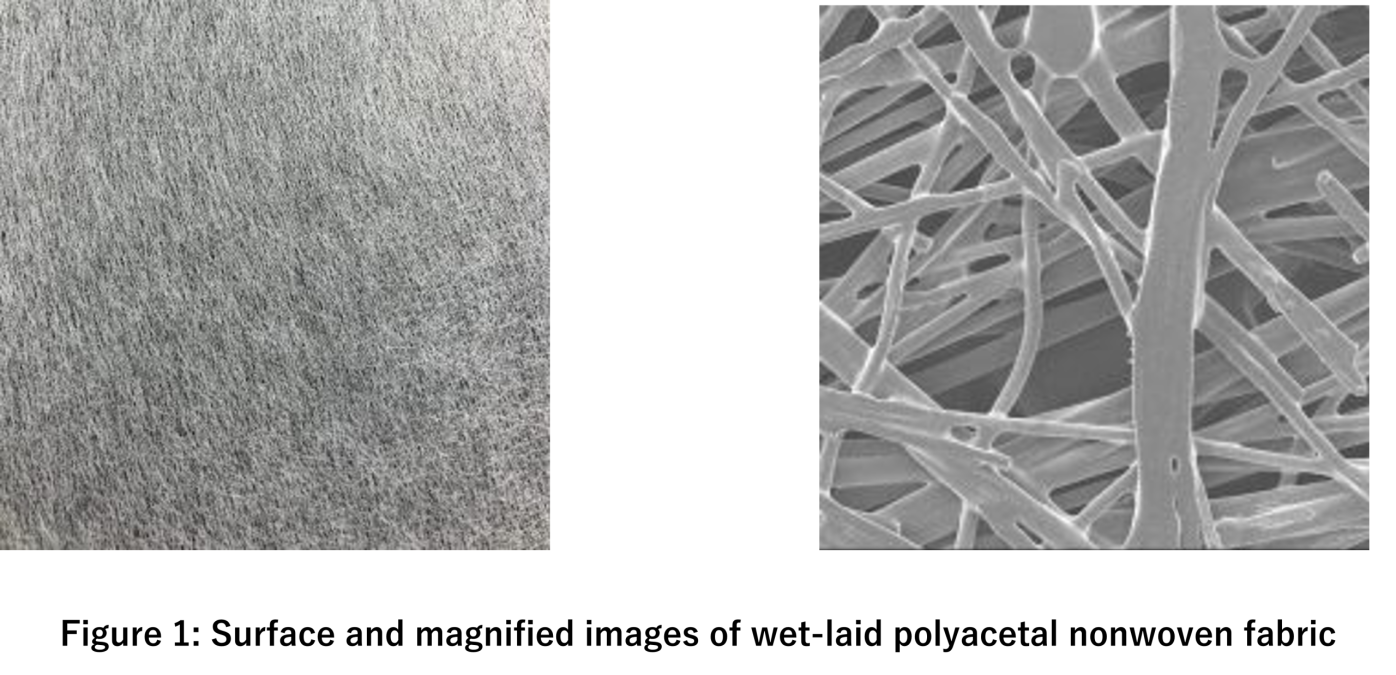

Polyacetal Fiber 100% Wet-Laid Nonwoven Fabric

PM Type (Newly Developed)

This is the world’s first wet-laid nonwoven fabric made from 100% POM (polyacetal) resin. It offers outstanding strength and durability, along with excellent resistance to chemicals and harsh environmental conditions. In addition, it is moisture-permeable, quick-drying, and hygienic—making it a truly unique nonwoven unlike anything before. By overcoming the many challenges long associated with converting POM into a nonwoven fabric, we have successfully brought this material into practical use.

Key Features

- Durable

- Chemical resistance

- Antibacterial properties

- Antifungal resistance

- Moisture permeability

- Breathable

Enlarged Image

Application Examples

Fuel filters

It exhibits strong resistance to organic solvents such as gasoline, ethanol, and oils, with little to no degradation even after prolonged exposure. Compared with conventional materials such as nylon and polyester, it provides a significantly higher safety margin.

Chemical filters

It offers excellent chemical resistance and heat resistance, maintaining stable performance against a wide range of chemicals. While caution is required with strong acids and strong alkalis, it exhibits high resistance to many other chemicals.

HVAC and cleanroom filters

Its structure contains countless fine pores between the fibers, allowing air and water vapor to pass through easily and providing high breathability and moisture permeability. Thanks to its highly durability, it is suitable for long-term use.

Medical nonwoven products

It features low water absorption and fast-drying properties, making it resistant to the growth of mold and bacteria. In addition, its excellent abrasion resistance helps minimize dust generation caused by wear, making it an ideal material for hygienic products such as highly durable gowns, filters resistant to biological fluids, and sterilizable masks.

Industrial sheet materials and insulation sheets

It has high strength and stiffness, as well as excellent fatigue resistance under repeated loading. Its extremely low water absorption (saturated water absorption of approximately 0.2–0.3%) results in minimal dimensional change due to humidity or water, providing outstanding dimensional stability.

Separation membranes

It combines selective permeability derived from its fibrous structure with excellent chemical resistance.

Abrasive nonwoven fabrics and industrial wipers

It exhibits one of the highest levels of wear and friction resistance among plastics, with minimal fuzzing and very low generation of wear particles even under repeated friction. It also offers excellent self-lubricating properties, making it highly durable and well suited for use as an abrasive material.

Waterproof and breathable sheets

Thanks to the water-repellent POM fibers and the porous structure between the fibers, liquid water is effectively blocked while water vapor is allowed to pass through. This enables its use as a functional sheet that combines both waterproof performance and breathability.

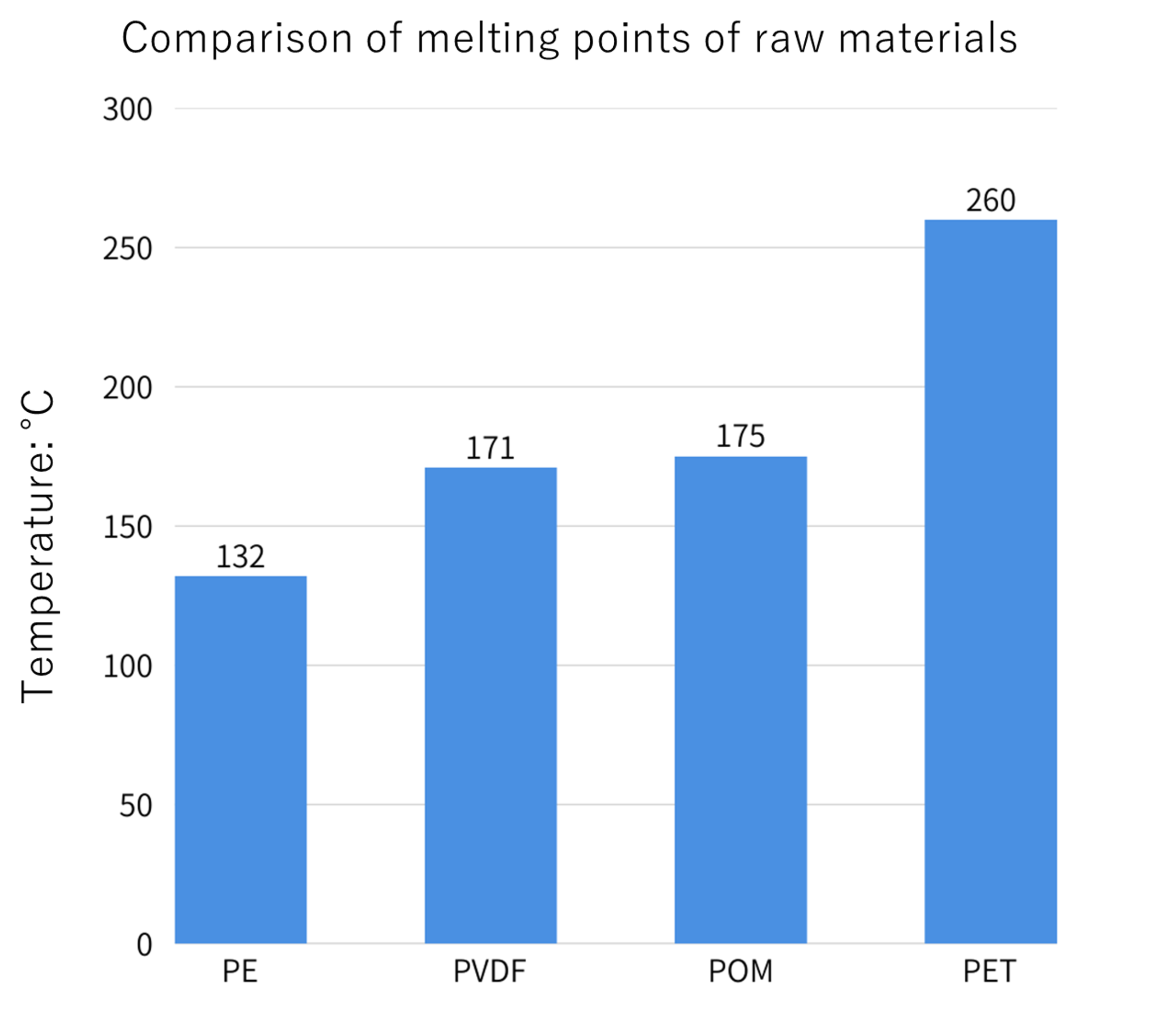

PM Type Melting point comparison data

PM Type Chemical resistance comparison data

| POM | PA66 | PPE | PBT | PC | |

|---|---|---|---|---|---|

|

Resistance to Organic Solvents |

++ | ++ | -~× | ++ | -~× |

|

Oil Resistance |

++ | ++ | -~× | ++ | -~× |

|

Acid Resistance (Low Concentration) |

+~- | - | ++ | ++ | +~- |

|

Alkali Resistance (High Concentration) |

+~- | +~- | ++ | -~× | -~× |

- ++ High resistance

- + Good resistance

- - Limited resistance

- × Not recommended

Grade List and Specifications

The PM type is a wet-laid nonwoven fabric manufactured from POM fibers with the characteristics listed below. It can be produced with a basis weight ranging from 20 to 100 g/m² and a thickness of 40 to 400 μm.

| Grade | Basis weight (g/㎡) | Thickness (μm) | Air permeability (cm3/cm2・s) |

|---|---|---|---|

| PM0060 | 63.0 | 252 | 341 |